Table of Contents

Magnetic saturation

| Stan Zurek, Magnetic saturation, Encyclopedia Magnetica, http://e-magnetica.pl/doku.php/magnetic_saturation {updated: 2025/02/15 15:38, accessed: 2025-11-04} |

Magnetic saturation - a phenomenon of non-linearity of magnetic properties of magnetic materials at high amplitude of magnetic excitation.1)2)3)4) At complete magnetic saturation, the values of magnetisation M (A/m) or magnetic polarisation J (T) reach the highest possible values of saturation magnetisation Msat or saturation polarisation Jsat, respectively, which are also a function of the chemical composition of the material and temperature.5)

S. Zurek, E-Magnetica.pl, CC-BY-4.0

However, the values of magnetic flux density B (T) or magnetic field strength H (A/m) do not reach saturation, so there are no corresponding values of Bsat or Hsat, even though such denotations can be encountered in the literature. H can be always increased and thus the associated μ0·H component of B will be also increased with increasing excitation. More explanation is provided below.

Ferromagnetic (and ferrimagnetic) materials respond with increased magnetisation to the applied external magnetic field.

At lower amplitudes, magnetic response of soft magnetic materials can be treated as quasi-linear (with certain simplifying assumptions), so that the excitation can be applied and response to be utilised over some amplitude useful in practical applications, such as magnetic cores of transformers, inductors, motors, and generators.

One of the practically useful properties of a magnetic core is its high permeability so that the magnetic flux can be guided in a controlled way in a magnetic circuit.6)

However, at higher excitation the onset of saturation decreases the value of permeability, eventually (at sufficiently high amplitude) making the effective permeability similar to that of non-magnetic materials (i.e. μr = 1). The inductance (and hence impedance) of the associated windings decreases significantly, leading to inrush and fault currents,7) which can be dangerous to the reliability or operation of the electromagnetic device.

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Therefore, magnetic saturation limits the practical operating range of electromagnetic devices (transformers, inductors, motors, generators) so that correct functioning outside of their nominal voltage, current, or frequency range might not be possible.

Depending on the type of analysis (theoretical or practical), there can be several types of saturation (explained in more detail in the following sections):

- complete theoretical magnetisation saturation at absolute zero temperature

- forced saturation (of precessing moments)

- theoretical magnetisation saturation or polarisation saturation at operating temperature

- technical saturation of magnetic domain

- operation above the “knee point” (above the quasi-linear region)

In semi-hard magnetic materials and hard magnetic materials, the saturation limits the amount of energy which can be stored in the magnetised material, but also coercivity is the other limiting factor.

Additionally, in all magnetic materials the level of saturation is related to the temperature of operation in an inverse way. The closer the temperature to the Curie temperature the lower the saturation.8)

Non-magnetic materials also react to magnetic field, but with much weaker response. Paramagnets (which have positive magnetic susceptibility due to unpaired magnetic moments) can become magnetically saturated, but only at very low temperatures and very high magnetic fields. Diamagnets (negative susceptibility, no unpaired magnetic moments) slightly oppose and weaken the applied magnetic field, and cannot be saturated.9)

Superconductors lose their superconducting state at sufficiently high magnetic fields. However, the physics of the superconductivity is different from the ordinary magnetic saturation of magnetic materials.10)

| → → → Helpful page? Support us! → → → | PayPal | ← ← ← Help us with just $0.10 per month? Come on…  ← ← ← |

Typical saturation values

There are many magnetic materials (alloys, ferrites, and composites) widely used in industry, for which well-established values of magnetic saturation are known.11)12) Significant research was carried out in the past in order to identify the material with the highest saturation magnetisation, and it was discovered that the Co-Fe alloys resulted with the highest values. However, cobalt is an expensive material, and thus it would be beneficial if alternative materials were identified. Recent research effort suggests that further optimisation can be achieved for new alloys, which push the boundaries to as high as 2.43 T.13)

| Typical saturation polarisation Jsat values 14)15)16) | |

|---|---|

| Fe70-Co25-Ni4-Si1 | 2.43 T |

| Co49-Fe49-V2 | 2.35 T |

| Fe | 2.15 T |

| Co | 2.15 T |

| Ni50-Fe50 | 1.60 T |

| Ni36-Fe64 | 1.30 T |

| Ni80-Fe15-Mo5 | 0.80 T |

| Ni77-Fe14-Cu5-Mo4 | 0.78 T |

| Ni | 0.608 T |

| FeFe2O4 | 0.603 T |

| CoFe2O4 | 0.534 T |

| MnFe2O4 | 0.503 T |

| NiFe2O4 | 0.340 T |

| MgFe2O4 | 0.151 T |

Nevertheless, magnetic saturation is only one parameter important for design of electromagnetic devices, and for optimum performance other values are also critical, such as power loss, or magnetic permeability.

Process of magnetisation

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Unpaired (uncompensated) magnetic dipole moments of atoms respond to the magnetic field by aligning to it.

The vector sum of all the individual moments averaged over a given volume represents magnetisation $M$ (A/m), or the equivalent quantity of magnetic polarisation $J$ (T) (which is the magnetisation scaled by the permeability of vacuum).17)18)19)

| magnetisation | $$ \vec{M} = \frac{\sum \vec{m_i}}{V} $$ | (A/m) |

| magnetic polarisation | $$ \vec{J} = μ_0 · \vec{M}$$ | (T) |

| where: $M$ - magnetisation (A/m), $\sum m_i$ - sum of magnetic moments of individual atoms (A·m2), $V$ - unit volume (m3), $J$ - magnetic polarisation (T), $μ_0$ - permeability of vacuum | ||

If the interactions between the neighbouring moments are strong enough they can spontaneously align over macroscopic distances, thus forming magnetic domains. Domains are separated by domain walls.20) (In paramagnets the interactions between the neighbours are too weak to form domains.)

In each domain, all the available moments are aligned, which is synonymous with local saturation, because no further alignment is possible at the given temperature.

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Copyright © Oles Hostanar

Copyright © Oles Hostanar

S. Zurek, E-Magnetica.pl, CC-BY-4.0

However, the domains within a magnetic material can point in opposing directions, so that the net magnetisation over the whole body of a ferromagnetic (or ferrimagnetic) material can be much smaller, even zero if the material is completely demagnetised.

If some magnetic field is applied to a demagnetised material, then the magnetic domains whose direction coincides with the applied field grow, at the expense of anti-aligned domains. The domain walls move accordingly to accommodate such changes.21)22)23)

During this process, a greater proportion of the whole volume will have domains aligned with the applied field, so the net magnetisation will increase proportionally. This is the range of operation in which the soft magnetic materials respond in a quasi-linear way to the applied excitation.

At even higher excitation, most of the volume become consumed by the domains aligned to the applied field. If their directions differ slightly, then eventually the vector will be rotated to be parallel with the field, but this requires much stronger amplitude to be achieved.

Once full alignment is achieved, then the internal magnetisation M or polarisation J cannot increase any more, and thus the full magnetic saturation values of magnetisation saturation Msat or polarisation saturation Jsat were achieved.

Further increase of the applied field cannot increase M or J. However, total magnetic response of the material is quantified in the value of magnetic flux density B, which always increases by some amount if H is increased.

| Magnetic flux density B | ||

|---|---|---|

| (expressed with polarisation J) | $$ \vec{B} = \vec{J} + μ_0 · \vec{H} $$ | (T) |

| (expressed with magnetisation M) | $$ \vec{B} = μ_0 · \vec{M} + μ_0 · \vec{H} $$ $$ \vec{B} = μ_0 · ( \vec{M} + \vec{H} )$$ | (T) |

The hysteresis and excess components of power loss in a magnetic material are related to the movements of domain walls.24)25) Therefore, if the amplitude of AC excitation is increased the loss will also increase, even though the material might be reaching (and exceeding) the state of full saturation at the peak of the excitation. This is because, with alternating magnetisation process the excitation reverses cyclically, and thus the resulting magnetisation, polarisation and flux density also reverse, with large domain movements as they cross through their corresponding zero values.

Saturation values: Hsat, Bsat, Msat, Jsat

S. Zurek, E-Magnetica.pl, CC-BY-4.0

The name “saturation” implies that no further increase of some quantity is possible. Full magnetic saturation is extremely difficult to achieve, and can happen only under very high excitation, not available in ordinary engineering applications.26)

The four main values which quantify the magnetic field in materials can be characterised as follows:

- magnetic field strength H - Theoretically, magnetic excitation can be always increased with increasing amount of applied electric current, therefore there is no limited value of “Hsat” arising from the magnetic properties of the magnetised material. There is a practical limitation to the amount of current which can be sustained in a conductor due to thermal and/or superconducting critical field limits, but these are not related to the magnetic saturation as understood from the viewpoint of aligning magnetic dipole moments.

- magnetic flux density B - If H is present, then the $μ_0·H$ component is always present, and therefore increasing the excitation in a form of H will always produce an increase in the corresponding magnetic flux density B (when discussing amplitudes near saturation). Hence, it is also not possible to achieve some limiting value of “Bsat” (and consequently there is no “saturation flux density” nor “saturation induction”). However, in practical cases it is sometimes useful to refer to the state of a material which is near saturation with some specific value of “Bsat”. Nevertheless, there is an implicit assumption that only some “technical saturation” is attained rather than full saturation. For example, in analysis of hysteresis loops of permanent magnets the “Bsat” (or “Bs”) point could mean a state when just Jsat was reached, even though B would continue to increase linearly beyond that point.27)

- in the CGS system the magnetic polarisation is referred to as intrinsic induction, and therefore it is possible to have saturation intrinsic induction Bi,sat which is typically just referred to as “saturation induction” Bsat or Bs even though it represents a different quantity from the ordinary induction28)

- magnetisation M - The magnetisation M in (A/m) is the vector average of the individual magnetic moment over a given volume. Once all the individual moments are completely aligned with the applied excitation then full saturation magnetisation Msat is achieved. Further increase of magnetic excitation will not produce further increase of M, because full alignment was already achieved.

- magnetic polarisation J - The value of polarisation J in (T) is the same quantity as M but scaled by the permeability of vacuum so that $J = μ_0 · M$, and therefore $J_{sat} = μ_0 · M_{sat}$. Therefore, there is also the limiting value of saturation polarisation Js.

Soft magnetic materials

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Soft magnetic materials are typically used within a range of excitation in which the difference between the flux density B and the polarisation J is negligible in practice. For example, an excitation of 10 kA/m would contribute only $μ_0 · H$ = 0.01 T, whereas saturation of various soft magnetic materials ranges between 0.3-2.4 T.

Above the “knee” of the non-linear magnetisation curve (see also explanation in the next sections), the permeability begins to decrease, and for ordinary devices such as transformers and motors this should be avoided.

However, certain applications make use of the saturation. For example, in a fluxgate sensor, some part of a magnetic core is cyclically saturated magnetically, with a symmetrical excitation. An additional magnetic field makes the saturation asymmetrical, which can be detected and correlated with the additional field, thus producing a mechanism for accurate measurement of that field.30)

Another example of saturation used as a wanted feature is the saturable fault current limiter technology. An appropriately shaped magnetic core is pre-saturated with superconducting windings or permanent magnets so that another winding placed on such core has very low impedance. Upon the occurrence of a fault current, the arising magnetomotive force opposes the saturating one, so that the core is taken instantly out of saturation, its permeability increases, inductance and reactance of the winding increases, and thus the fault current is limited accordingly.31)

Semi-hard and hard magnetic materials

S. Zurek, E-Magnetica.pl, CC-BY-4.0

In semi-hard, and especially in hard magnetic materials the range of applied magnetic field strength can reach high and very high values, where the difference between J and B is so significant that a distinction has to be made between the B-H and J-H loops.

When a sufficiently high magnetic field is applied to a permanent magnet then a saturation state is achieved (Jsat). Then, after removing the applied field a significant amount of energy is stored in the internal magnetic field of the material. This energy can be stored for infinitely long time (for all practical purposes) if the material is not subjected to negative field or high temperature.

M. Dośpiał, MDPI, CC-BY-4.0

For strong permanent magnets such as NdFeB the application of a magnetic field in an opposing direction, even such that the resulting B reduces to zero (BHC point) the magnet remains magnetised. This inherent energy storage is a basis for information storage (hard drives) and for generation of strong magnetic fields by permanent magnets.

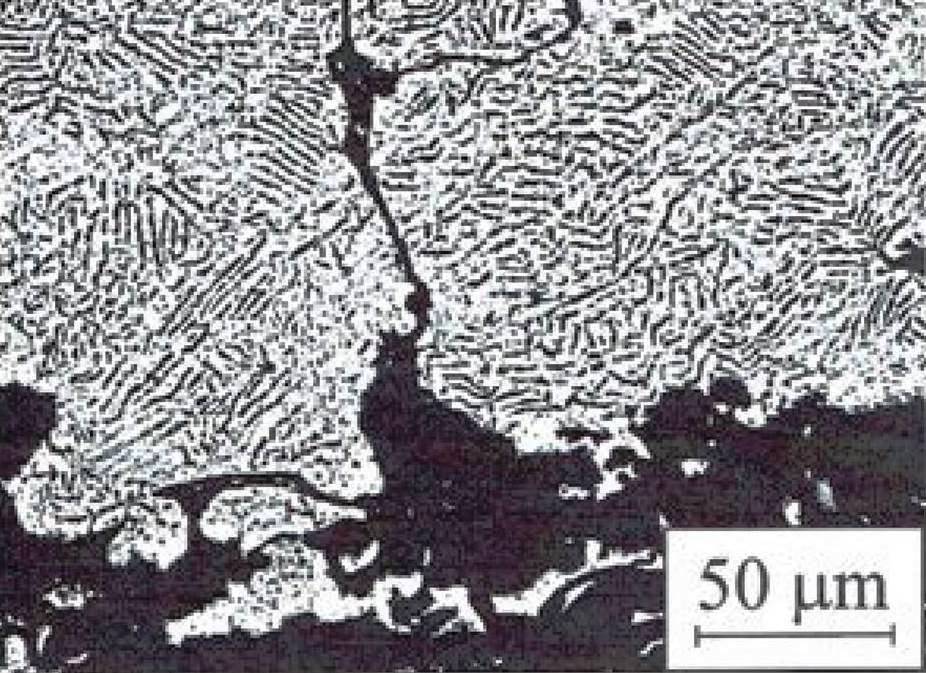

In permanent magnets the size of grains and domains is very small, which helps in strong domain wall pinning thus increasing the amount of energy which can be stored in the magnetic field.34)35)

Permanent magnets are typically in a magnetic circuit with an air gap, which produces demagnetising effect and thus makes the magnet to operate in the second quadrant of the hysteresis loop, in any case away from saturation. However, a magnet must be first exposed to very high (saturating, or almost saturating field) before it can become magnetised.

Anisotropy

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Ordinary magnetic materials can be saturated in a “positive” or “negative” direction (or in any other direction in 3D), with the same value of saturation, but perhaps with just negative sign (if “negative” excitation was applied).37)

Highly anisotropic materials such as grain-oriented electrical steel have some privileged directions (“easy magnetisation direction”) in which the material responds with higher M, J or B at lower applied field H. It is therefore easier to saturate the material when the magnetic excitation is applied in that direction.

However, ultimately, the limiting value of saturation Jsat or Msat is the same regardless of the direction of applied field, because it is a property related to the chemical composition of the material, not the crystallographic structure as such. This is because a saturation is a state in which all the magnetic moments are aligned, regardless the direction.38)

Similar saturation behaviour can be observed if the anisotropy is caused by the shape anisotropy of the sample, rather than the intrinsic properties of the material of the sample.39)

Temperature

S. Zurek, E-Magnetica.pl, CC-BY-4.0

The phenomenon of ferromagnetism is linked to the spontaneous alignment of magnetic moments due to the neighbour-neighbour interaction. These interactions are counteracted by thermal agitation of the constituting atoms. If the temperature increases then there is more thermal energy and the magnetic interactions are impacted by a greater amount. At sufficiently high temperature, beyond Curie temperature, ferromagnets become paramagnetic because the spontaneous alignment of magnetic moments cannot be sustained in the overpowering thermal agitation.

On the other hand, if the temperature is lower, then the magnetic interactions are impacted to a lesser degree. For instance, gadolinium is paramagnetic at room temperature, but becomes ferromagnetic upon cooling to lower values.

S. Zurek, E-Magnetica.pl, CC-BY-4.0

At the temperatures near absolute zero the highest possible spontaneous alignment can be achieved, with the highest possible values of saturation magnetisation Msat or the equivalent saturation polarisation Jsat for the given material. These thermal effects have implications on “technical saturation” (described in more detail below).

| Curie temperature for ferromagnetic elements43) |

||

|---|---|---|

| (°C) | (K) | |

| cobalt Co | 1131 | 1404 |

| iron Fe | 770 | 1043 |

| nickel Ni | 358 | 631 |

| gadolinium Gd | 20 | 293 |

| terbium Tb | -54 | 219 |

| dysprosium Dy | -188 | 85 |

| thulium Tm | -241 | 32 |

| erbium Eb | -253.5 | 19.5 |

| holmium Ho | -254 | 19 |

If the saturation magnetisation at absolute zero temperature is taken as the reference then, as shown in the illustration, the spontaneous magnetisation M decreases the more rapidly the closer the material is to its Curie temperature. The shape of the M/Msat curve is related to the configuration of unpaired magnetic moments in the atomic structure of the given element.44)

If an electromagnetic device has to operate at elevated temperatures these effects become important. For example, electric generators inside jet engines can be exposed to high temperatures (even exceeding 200 °C) and therefore the required magnetic properties must be ensured for the built-in electric generator.45) This applies to the magnetic cores as well as permanent magnets.

Also, in induction heating of steel for hardening, the metal might be heated above its Curie temperature, which has to be taken into account during the heating process, because it changes the amount of energy that can be delivered to the heated element by electromagnetic means.46)

Information storage on semi-hard magnetic materials (e.g. hard drives) relies on retention of local magnetisation over long periods of time. This process is limited by superparamagnetic limit, which dictates the thermal stability of the magnetic storing structure.47)

Technical saturation - knee point

The magnetisation curve of soft magnetic materials has a characteristic shape, which can be split into two simplified regions.48)

At lower excitation, the material has relatively high permeability and often it can be approximated with a constant magnetic permeability so that the material can be thought of as responding in a quasi-linear way to the applied excitation. Operation of a magnetic core in this region is predictable and generally safe.49)

At high amplitude of excitation the material is operating close to saturation, and its permeability reduces significantly. If a device was designed to operate in the quasi-linear region then entering the saturation (e.g. as caused by some fault condition) can be dangerous and can lead to a permanent failure.

Therefore, in some practical application it is useful to distinguish between these two regions, marking the “knee” point which separates them. Therefore, the colloquial meaning of the “knee point” is the location on a magnetisation curve which lies just above the quasi-linear region, and anything above the knee is referred to as “saturation”,50) which strictly speaking is incorrect (because full magnetic saturation requires much higher excitation). However the technical saturation is a useful concept, both from a practical and theoretical viewpoint.

From a theoretical viewpoint, the state of technical saturation can be also referred to in the process of magnetisation. When a sufficiently high magnetic excitation is applied to a given magnetic material, eventually a single-domain state will be reached. This single-domain state represents the theoretical technical saturation, because all the magnetic moments are parallel and thus the material is saturated to Msat in the direction parallel to that domain. However, if the exciting field is applied as some other angle and even higher value will be applied (so that the energy of anisotropy can be overcome), then the domain will eventually rotate to become parallel to the applied field. Moreover, even the precession of dipoles can be forced to lower angles, and then the complete saturation M0 will be reached. This slow increase of magnetisation due to rotation in high applied field is known as forced magnetisation.51)

In some specific practical or engineering cases the knee point is defined quite precisely, as it is for instance for current transformers (CT) used in electricity distribution industry.52)53) For example, the international standard IEC 61869 defines the knee point as such at which an incremental increase of AC excitation voltage (at nominal operating frequency) by 10% causes the increase of resulting current by 50%.54) Therefore, an increase in one quantity causes a disproportional increase in the related quantity, and thus the magnetic non-linearity (the location of the “knee”) can be detected simply by measuring the associated electrical signals.

Another approach is described in the standard IEEE C57.13 which gives two other definitions, referred to ANSI 45° and ANSI 30°. With the applied AC voltage plotted against the resulting current with the same scaling (e.g. log-log) the knee point is where the line tangential to the plotted V-I curve lies at an angle of 45° or 30°, respectively.55)

In a CT it is important to know where the knee point lies, because the accuracy of transducing the primary current can be guaranteed only below this point. Additionally, the voltage across the winding of a CT is related to the amount of power that can be delivered to the CT burden (and for example to safely operate a protection relay). Therefore, the measurement of the knee point (saturation point, or saturation voltage) is a tool for verification of the capabilities of a given CT. There are commercial products for such measurements.56)

Yet another definition of practical magnetic saturation is given in the standard IEC 60404-7:2019.57) Practically sufficient level of saturation is obtained if increasing the saturating field by 50% does not increase the measured coercivity by more than 1%. The saturating field can be applied by an electromagnet (solenoid) or a permanent magnet.58) In commercial coercimeters saturation of soft magnetic materials is achieved typically with a field of 140-450 kA/m, which can be obtained by DC current from a variable DC power source, or by pulse methods from a LC circuit.59)60)

Inrush current

If an ordinary AC transformer (50/60 Hz) is energised at a random instant of time with a sinusoidal voltage, then the magnetic flux can build up and add to the remanence, and thus push the magnetic core into magnetic saturation (i.e. deep above the knee of magnetisation curve).61)62)63)

X. Wen, J. Zhang, H. Lu, MDPI, CC-BY-4.0

X. Wen, J. Zhang, H. Lu, MDPI, CC-BY-4.0

Under such condition, the impedance of the windings can drop significantly because of technical saturation. The AC transformers are typically energised from a relatively “stiff” voltage source (electricity grid) and therefore fixed voltage amplitude and low winding impedance results in elevated amplitude of resultant current, at the level similar to a fault (such as short circuit). In the illustration, in the measured data for a small transformer the worst-case peak current reaches up to 1.1 A, even though the nominal current is 0.15 A, thus there was an order of magnitude increase,65) and it can last for relatively long time of up to several seconds.66)

Similar inrush events can happen in electric motors.67)

There are multiple implications of inrush current events, including thermal, mechanical, and protection:68)69)

- Thermal - Power loss dissipated in the windings is proportional to the square of current. Therefore, if the the current increases by a factor of 10 then the instantaneous power loss would increase by a factor of around 100. This can cause overheating of electrical insulation and thus catastrophic electrical failure of such machine.

- Mechanical - Fault-like current levels in the windings can exert mechanical forces large enough that they can distort and bend the windings, to the point of destruction,70) especially if high-voltage insulation was damaged in such process. Methods such as frequency-sweep analysis can detect physical distortions of the windings in a non-destructive way by a low-energy electrical measurements.

- Protection - high-power electrical machines such as transformers and motors are protected against fault currents (such as short-circuit or locked rotor conditions) by suitable circuit breakers or fuses. The activation level of such protection has to be low enough to protect the devices, and the lower the threshold the better level of protection. However, if the tripping level is set too low then every time the device is powered and an inrush current event happens then the protection would activate every time, resulting in nuisance tripping. In order to cater for inrush currents, there are circuit breakers which have “delayed” action so that a relatively short overload in a form of inrush current would not activate it. This is also one of the main reasons why there are “slow” and “fast” fuses, because a fast fuse would be activated every time by an inrush current caused by magnetic saturation of a the magnetic core.

Demagnetisation

The process of demagnetisation means that a material which was previously magnetised or saturated and it remains in some B ≠ 0 (at H = 0) state is brought to the state B = 0 (at H = 0). This minimises the amount of energy stored in the magnetic field outside and inside the volume of the magnetic material.

A magnetic material can be demagnetised in two basic ways: reducing AC excitation (most popular) and thermal (rarely used, but theoretically effective).

In the reducing AC excitation method the excitation is applied in the alternating way (e.g. sinusoidal or switched DC). For correct demagnetisation, the applied AC magnetisation needs to have the amplitude at least equal, or higher than the excitation which was previously applied to the material. The AC amplitude is then slowly reduced, so that that the material is exposed to multiple cycles of excitation in a “positive” and “negative” direction. Such excitation makes the B-H curve to trace a reducing spiral. If the demagnetisation is successful, the material ends at the state H = 0 and B = 0.

If the amplitude is reduces too quickly, in too few steps, then the demagnetisation process might not be successful, such that B ≠ 0 at H = 0. Similar applies if the applied excitation is lower than the previous level of magnetic field to which the material was exposed - because then it might not be possible to fully “erase” the magnetic history of the material.71)

S. Zurek, E-Magnetica.pl, CC-BY-4.0

In the thermal method the magnetised material has to be heated to a temperature above Curie temperature Tc of the given material. The thermal agitation of magnetic moments can destroy their spontaneous alignment, and upon cooling the material will become demagnetised, due to randomised orientation of all the contributing domains. However, in practice this method is used very rarely, because for most magnetic alloys Tc is several hundred degrees Celsius, which would damage other associated materials such as varnish used for protection of the magnetic core or the windings.

Remanence

S. Zurek, E-Magnetica.pl, CC-BY-4.0

It should be noted that $ \vec{B} = \vec{J} + μ_0 · \vec{H} $, and thus at H=0 it is true that $B_{H=0} = J_{H=0}$. If the material was first saturated, and then the external excitation was brought back to zero then the material will be put in the state of H=0, and it will retain some level of magnetised state. This “remaining” amount of B or J is called a remanence, and can be denoted by Br or Jr (both values have the same unit of tesla, T).

The equality Br = Jr holds also for permanent magnets (see illustration above).

The remanence point can be also quantified as Mr. The value can be determined simply by first measuring the value of Jr (T) and dividing it by μ0 (H/m), thus obtaining Mr (A/m).

In some literature, the definition of remanence requires the material to be saturated first, so the remanence value will be always the same for the same material under the same conditions.

However, in some analyses the “full” saturation is not required so that the value of remanence become a function of the magnetic history, so that the “remanence” can vary from its maximum value all the way to zero (if the material is nearly demagnetised). This is for instance the studies of paleomagnetism in which the term “remanence” can refer to the amount of remnant flux density of some mineral due to the Earth's magnetic field (without magnetic saturation).72)73)

Coercivity

After saturation, if the excitation is first reduced to zero (H = 0), and then slowly applied in the negative direction through the second quadrant, until B = 0, then a point called coercivity Hc will be reached. And because H has to be applied in a negative direction, the value of Hc is negative.

In soft magnetic materials, the value of Hc is relatively low, the lower the better. For that reason the component $μ_0 · \vec{H}$ in the equation $\vec{B} = \vec{J} + μ_0 · \vec{H}$ is negligibly smaller than $J$ and therefore $J \approx B$ = 0 at the coercivity point of $H_c$.

In hard magnetic materials the value of Hc is relatively high, the higher the better. The contribution of $μ_0 · \vec{H}$ is no longer negligible and thus two points have to be distinguished (see also illustration in previous sections):74)

- at B = 0 the coercivity value is BHc

- at J = 0 the coercivity value is JHc

- and such that: | BHc | < | JHc |

As with remanence, coercivity can be defined as measured after saturation so that it has always the same value, related to material properties.

But in other types of analyses it can be useful to use the “coercivity” as measured after other amplitudes or modes of excitation (e.g. varying frequency), for any B-H loop crossing the B=0 level.75)

Rotational magnetisation

In magnetic cores of rotating and polyphase machines there are regions which are magnetised in a rotating way.

As mentioned above, the hysteresis and excess component of power loss is related to the movement of domain walls. As the material is excited with high amplitude close to saturation, then if the magnetising field rotates then there are fewer domain walls, and at full saturation the material has just one magnetic domain (no domain walls) rotating together with the applied field.76)

The eddy currents are still induced in the the magnetised material and thus they generate loss, which increases proportionally to the square of frequency. But at very slow angular frequency of rotation the power loss in the material can decrease to very small values, much lower than the losses under AC magnetisation, as shown below for some typical measured data. The loss under rotational magnetisation reaches a characteristic peak at about Brot between 1.4 - 1.7 T for electrical steels and begins to decrease for higher excitation.77)

If the frequency of rotation is increased then the eddy currents become the dominant mechanism for loss generation and thus the peak in the power loss characteristics is less pronounced, and does not occur for even higher frequencies.78)

S. Zurek, E-Magnetica.pl, CC-BY-4.0

S. Zurek, E-Magnetica.pl, CC-BY-4.0