Table of Contents

Litz wire

| Stan Zurek, Litz wire, Encyclopedia Magnetica, https://e-magnetica.pl/doku.php/litz_wire |

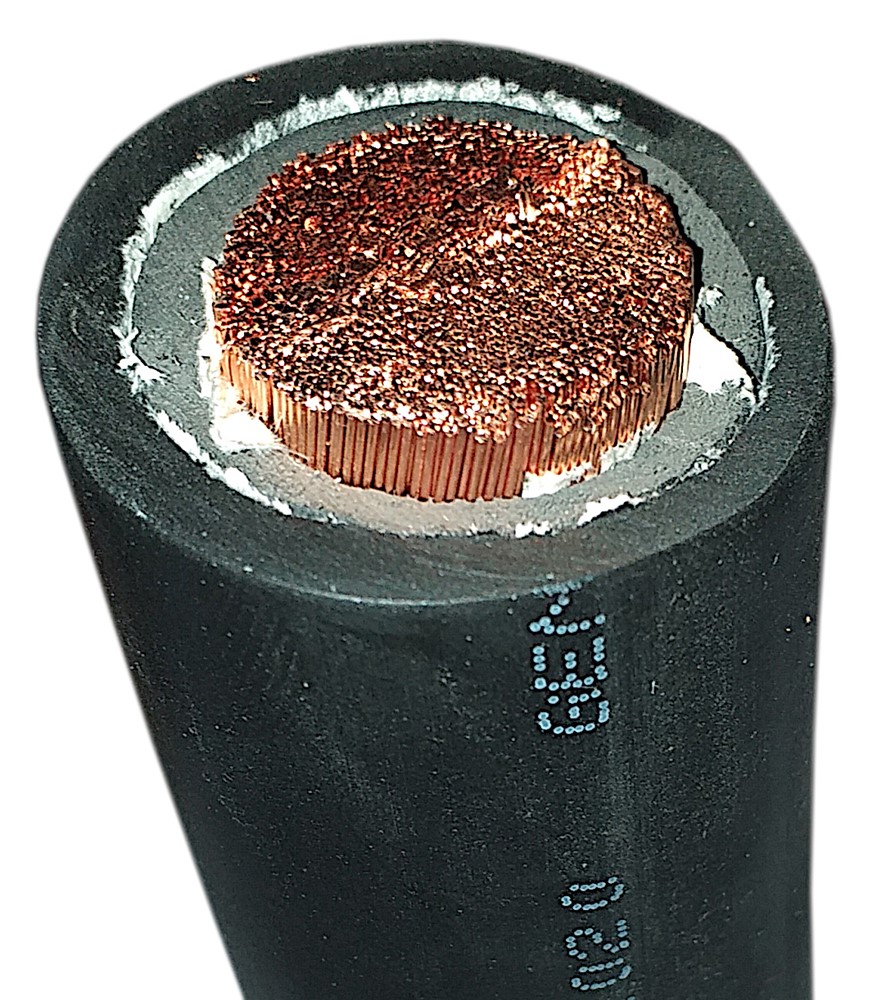

Litz wire - a type of winding wire used for windings and coils operating at high frequencies, such that solid wire or copper tape cannot be used due to skin effect and proximity effect.

by Alisdojo, Wikimedia Commons, CC0-1.0

by Alisdojo, Wikimedia Commons, CC0-1.0

Litz wire is made from strands, which are insulated from each other, typically with enamel (by using strands of enamelled wire to twist together).

The electrical insulation prevents the current to migrate from one strand to the next.

The twisting is carefully arranged so that each strand occupies each possible position within the whole bunch. This minimises differences between inductances and impedances of each strand and helps in equalising the currents flowing in them.

Litz wire is more expensive than a regular round enamelled wire and therefore its use is not justified for DC applications.

Also, for low-frequency applications in many cases the simple round wire is sufficient. Unless special techniques are employed, Litz wires are needed for operation at tens of kHz and above.

The name “Litz” comes from the German “litzendraht” meaning “woven wire”.1)

S. Zurek, E-Magnetica.pl, CC-BY-4.0

S. Zurek, E-Magnetica.pl, CC-BY-4.0

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Comparison to ordinary stranded wire

In ordinary stranded wires the individual strands are made from bare copper and not insulated from each other. The strands touch each other and the current can freely flow between the strands.

The ordinary wires are stranded for the primary reason of increasing their mechanical flexibility, in order to facilitate bending around tighter corners and reduce potential damage due to strain.

Litz wires are stranded for the primary reason of increasing the combined surface area of copper so that the skin effect consequences are reduced at higher frequencies.

| → → → Helpful page? Support us! → → → | PayPal | ← ← ← Help us with just $0.10 per month? Come on…  ← ← ← |

Construction

Depending on application, a Litz wire has can have from seven to hundreds or even thousands of strands, with decreasing thickness of strands for increasing frequency.

S. Zurek, E-Magnetica.pl, CC-BY-4.0

S. Zurek, E-Magnetica.pl, CC-BY-4.0

S. Zurek, E-Magnetica.pl, CC-BY-4.0

Cost

Typical example of Litz wire cost (as of 2011)2) are shown in the table below. All wires have an equivalent cross-sectiona area comparable to 1 strand of 10 AWG wire.

| Stranding | Relative cost factor | Frequency at which skin depth equals conductor radius |

|---|---|---|

| 1 strand of 10 AWG wire | 1.00 | 2.6 kHz |

| 10 strands of 20 AWG wire | 1.86 | 26.5 kHz |

| 26 strands of 24 AWG wire | 2.73 | 64.4 kHz |

| 66 strands of 28 AWG wire | 3.20 | 171 kHz |

| 110 strands of 30 AWG wire | 3.26 | 272 kHz |

| 210 strands of 33 AWG wire | 3.46 | 554 kHz |

Soldering

Solderable Litz wires (with self-fluxing enamel) are more difficult to solder than regular stranded or single-core wires. This difficulty arises from the fact that each strand has to be electrically connected at the given soldered end. The enamel impedes distribution of heat and it is much more difficult to heat up the inner strands sufficiently for the solder to wet all the strands.

Therefore, certain amount of experimentation is always required for soldering or tinning of Litz wires.

Self-fluxing enamel

Wires with smaller total cross-section area can be soldered directly with a soldering iron, but the method is not straighforward an requires practice. If the strands are thicker, it might be beneficial to apply the heat to the very ends of the strands, because the heat can penetrate more quickly through the exposed copper (see the image of strands taken under microscope).

Manufacturers, especially for thick wires, recommend the use of solder pot. The quantity of the molten solder in the pot has to be large enough so that the solder will not be overcooled by the immersion of the wire.3)

Traditionally 50/50 or 60/40 tin-lead solder was used, but lead-free solder formulations are suitable too: Sn-Ag, Sn-Ag/Cu, Sn-Cu. Soldering temperature depends on many factors, with the most important ones being the manufacturer recomendations for the enamel and for the type of solder. Same applies for the immersion time, which is typically around 2 seconds, but can be up to 60 seconds for very thick bundles. The best combination is typically obtained individually by experiments for a given type of connections.

Typical values can be are given as follows:4)

| Enamel type | Diameter | Temperature | Immersion time |

|---|---|---|---|

| Polyurethane | < 6 mm | 415°C | 10 s |

| > 6 mm | 430°C | 20 s | |

| Polyester | < 6 mm | 470°C | 15 s |

| > 6 mm | 470°C | 25 s |

With the solder pot method, the heat can travel further into the wire and this can damage insulation or impact flexibility of the wire. To reduce this effect a heat sink can be used, in a form of appropriately shaped metal pliers (clamped directly above the soldered connection) which will absorb the heat during the immersion.5)

Flux is generally not required for the polyurethane-based enamels, but its use can be beneficial, especially for larger or compact assemblies, polyester enamel, and in cases with longer soldering times. Special flux (“non-activated” type R or “fully-activated” RA) may be used.

Immediately after removal fom the solder pot the excess of the solder (and flux) should be removed with a clean cloth.

During the process, eye and face protection should be worn, and ventilated air hood is recommended to prevent breathing of the fumes.

Other type of insulation

Insulation must be removed if it cannot be soldered through. The removal can be achieved by several methods, depending on application, type of insulation, and cost-effectiveness of a process:

- mechanical - abrasive removal of insulation by a physical contact with a brush or a blade6)

- fusing - a combination of heat and pressure to displace enamel and replace it with solder7) (the process is similar to spot welding, but optimised for fusing copper)

- chemical - immersion in liquid or gel solvent, which dissolves the insulation (acids are not used because of the danger of corroding the coper)8)

- flame - the insulation is removed by an oxidising flame9)

- fused salts - salts are melted in a pot similar to the solder pot, and the wires are immersed until the enamel is dissolved10)

- crimping - special crimps can be used which can punch directly through the enamel11)

The soldering or tinning can be then performed as for ordinary or self-fluxing wires (soldering iron, solder pot, etc.)

Cleaning can be performed with a brush and isopropyl alcohol12), but this depends strongly on the application and specification of the wire.